We modified the automation in an interesting mechanical solution building a few days ago - here's the story.

In the client's house, ducted fan coils were integrated into the heat recovery ventilation system. The ventilation system consists of separate units for each of the building's two floors, each with its own fan coil. During the summer, the system circulates cold water through the fan coils' heat exchangers, cooling the interior as the ventilation unit blows air through them. The ventilation diffusers cannot be regulated individually.

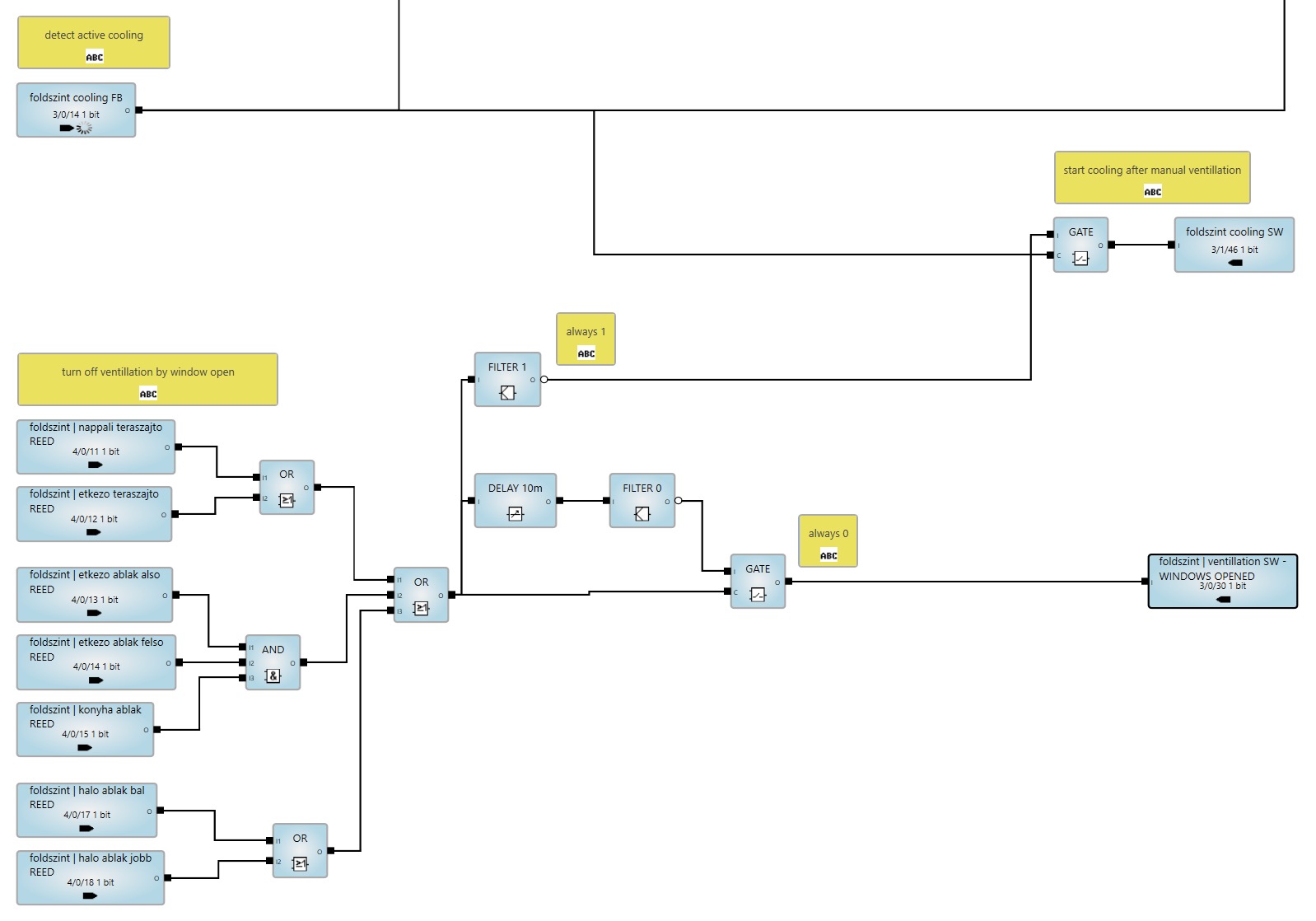

Our task was to stop the cooling along with the ventilation 10 minutes after certain windows or doors are opened, and to restart it if necessary after they are closed. To stop the cooling, we needed to simultaneously shut down the fan coils' circulating pumps, fans, and the ventilation unit itself.

Stopping the system is straightforward: we route the events from the window/door open sensors through a few AND/OR gates to start a 10-minute timer. If the openings remain open after the timer expires, we send a shutdown command to the cooling actuator ports and block them from turning back on to prevent the automatic cooling from starting while the building is being manually ventilated.

The more interesting challenge is restarting the cooling after manual ventilation. The cooling is controlled by a heating actuator that decides whether cooling is needed based on the desired and measured temperature data. When cooling is necessary, it sends the activation command to the relevant actuators.

When the cooling block is lifted, we cannot ask the cooling actuator to reassess whether cooling is needed and, if so, send the activation command. Fortunately, it can indicate if cooling is required, so the logic that lifts the block can reactivate the cooling.

In PLC terms, it looks like this: